Fan coils are used to provide ventilation in buildings and depending on the season, they can also deliver heating or cooling. Ventilation is accomplished with a built-in fan, while heating and cooling are achieved by circulating hot or cold water through the piping coils in the unit. A horizontal fan coil is designed for a ceiling installation, while a vertical fan coil is designed for a wall installation.

In building HVAC systems, multiple fan coils are connected to the same piping loop, which carries chilled water or hot water as needed. Based on how their piping is connected, fan coils can be classified into two-pipe or four-pipe systems:

- In a two-pipe configuration, fan coils only connect to one supply pipe and one return pipe. This means that all fan coils in the loop get either hot water or cold water, and the entire system operates in heating mode or cooling mode.

- In a four-pipe configuration, fan coils have two supply pipes and two return pipes, giving access to both hot water and chilled water. As a result, some fan coils deliver cooling while others deliver heating.

There are some cases in which a building may require simultaneous heating and cooling. For example, data centers require cooling all year long to eliminate the heat produced by servers, even if other building areas require heating.

Fan coils are not designed as stand-alone HVAC systems, since they require an external source of chilled or hot water, such as a chiller or boiler. Some modern designs use heat pumps, which can produce either hot or cold water as needed.

Installation Options for Horizontal Fan Coils

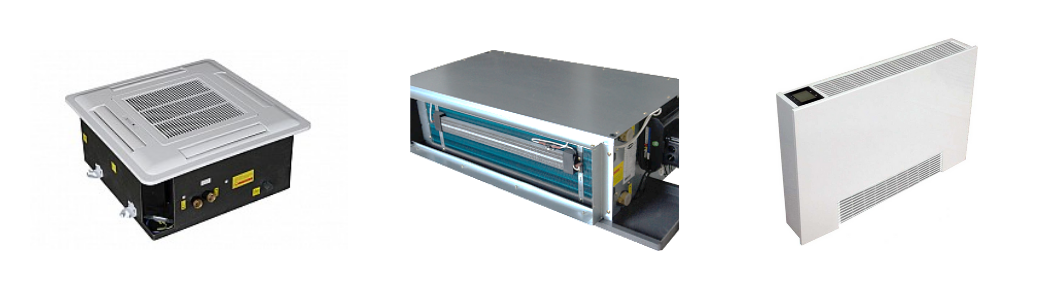

A horizontal fan coil is designed for a ceiling installation, as previously mentioned. However, there are two main installation options, and each uses a different product:

- Cassette units such as the MDL Verano Cassette Fan Coil are designed for direct insertion into the ceiling. They are visible, and they have built-in diffusers to discharge air directly into conditioned spaces.

- Traditional units like the MDL Verano ECM Fan Coil are mounted above the ceiling and out of sight. Instead of blowing air directly into conditioned spaces, they use separate air ducts and diffusers.

While the configuration changes, both types of fan coil are designed for the same function: blowing air through a piping coil that carries hot or chilled water, to deliver ventilation combined with heating or cooling.

ECM stands for electronically commutated motor, a type of motor that can adjust fan speed depending on ventilation needs. Compared with a conventional single-speed motor driving a fan, an ECM can achieve electricity savings of up to 75%, according to the US Department of Energy. EC motors are also known as brushless DC motors.

Regardless of the type of horizontal fan coil used in a project, it must be properly sized to deliver adequate ventilation and temperature control. Oversized fans represent a waste of energy, while undersized fans cannot provide enough air for the corresponding area. HVAC engineers calculate ventilation rates according to the ANSI/ASHRAE Standard 62.1 in the case of commercial projects, and ANSI/ASHRAE Standard 62.2 for residential projects.

Importance of Providing Adequate Maintenance for Fan Coils

Since a horizontal fan coil provides ventilation and temperature control for indoor spaces, conserving air quality is very important. This means the fan coil and its ducts must be kept clean of air pollutants like dust and mold. Otherwise, the unit may spread these particles indoors, causing respiratory irritation and allergies.

Another threat that must be controlled is the Legionella bacteria, which tends to grow in stagnant and warm water, and fan coil condensate pans are no exception. This bacteria is very dangerous, since it causes Legionnaires’ disease – a type of pneumonia with a fatality rate of around 10%. However, this should not be a problem when using a professionally designed HVAC system that gets proper maintenance.

In response to the COVID-19 pandemic, ASHRAE has published recommendations to improve indoor air quality in buildings. These can be applied in HVAC systems that use fan coils:

- Increasing ventilation with outdoor air, while reducing indoor air recirculation.

- Using air filters with at least a MERV 13 rating.

- Using ultraviolet germicidal irradiation in fan coils and air ducts to inactivate germs.

At MDL we offer innovative heating and cooling solutions for the North American market, including energy efficient fan coils. Our HVAC systems offer energy savings in the range of 12-45% compared with conventional installations. Contact us now and we can help you find the optimal heating and cooling solution for your building.